In yesterday’s Safety Sunday article on Staying Lead Safe in One’s Own Home, we briefly talked about issues with older pipes that contain lead in them. Shortly after that on Twitter I was discussing a bathroom plumbing issue where I recommended that they check out PEX piping to re-pipe those fixtures. While I love Twitter for being able to get quick thoughts & ideas across, when it comes to longer drawn out discussions it doesn’t fly.

What is PEX?

PEX stands for cross-linked polyethylene& was developed in the 60’s & introduced into the US in the 80’s where its popularity continues to grow year after year. There are three general methods for producing PEX tubing, the “Engle” or “Peroxide” (aka PEX-A) method, the “Silane” (aka PEX-B) method, and the “E-beam / electron or electronic-beam” (aka PEX-C) method. While most would consider the “C” variant the most green, the “A” variant is the strongest and produces the most uniform piping around. Seeing my name is attached to the project, and the product is made by a local company REHAU, it is a no brainer that we go with the “A” Variant that even comes color coded.

PEX stands for cross-linked polyethylene& was developed in the 60’s & introduced into the US in the 80’s where its popularity continues to grow year after year. There are three general methods for producing PEX tubing, the “Engle” or “Peroxide” (aka PEX-A) method, the “Silane” (aka PEX-B) method, and the “E-beam / electron or electronic-beam” (aka PEX-C) method. While most would consider the “C” variant the most green, the “A” variant is the strongest and produces the most uniform piping around. Seeing my name is attached to the project, and the product is made by a local company REHAU, it is a no brainer that we go with the “A” Variant that even comes color coded.

PEX Appeal:

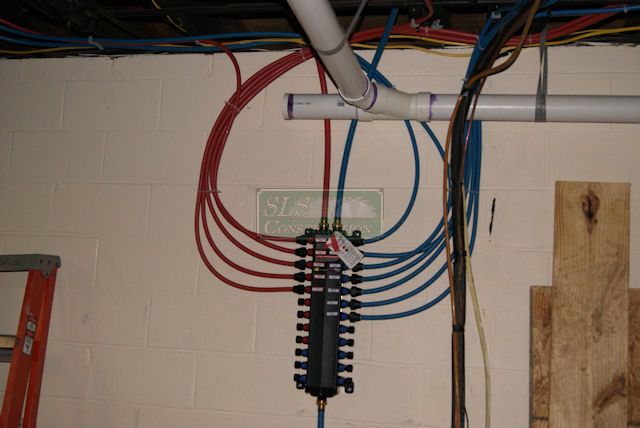

Part of PEX’s appeal is based on the ease of installation, its reliability, overall cost, and its flexibility which you can see from the picture above. Another major selling point is its thermal properties and its ability to withstand freezing temperatures better than copper. Because of its thermal properties it will also reduce the rate of heat loss from the lines and help eliminate condensation issues.

Part of PEX’s appeal is based on the ease of installation, its reliability, overall cost, and its flexibility which you can see from the picture above. Another major selling point is its thermal properties and its ability to withstand freezing temperatures better than copper. Because of its thermal properties it will also reduce the rate of heat loss from the lines and help eliminate condensation issues.

Why PEX for Retrofit’s & Re-pipes?

While these pictures are taken from one of our recent projects in Vestavia Hills where we have fully gutted both bathrooms – you don’t need to in many cases to install this product. In many cases a small access hole is all that is required to run a new PEX line to a faucet or toilet. While we showed just how flexible it is above, the nice item is that it also can be pulled just like an electrician would fish a new circuit. Another great selling point is that one can purchase it on rolls up to 500’ long, which means that the only fittings required in many cases are the one at the supply point and the one at the end of the run. Seeing most plumbing leaks occur at the fittings, this sure does cut down on any potential trouble areas.

Home Run, Traditional, or Hybrid?

Most traditional plumbing systems have a supply line that branches off and feeds every single fixture, which can cause some issues when more than one fixture is calling for water at the same time. While the supply line should reduce in size from the original fixture to the last one, that is rarely done and can exacerbate the issue above. The other major issue is when one calls for Hot Water from the farthest fixture as the hot water has to run all the way from the Hot Water Heater and past the supplies to all the fixtures. The other downside to this system is the lack of shutoffs and the amount of fittings required.

With the introduction of PEX it made it easier on plumbers to utilize what is referred to as a “Home Run System.” A Home Run system is where the water still comes from the same supply line but it runs into a manifold or distribution point. From this manifold a line is run to each fixture generally utilizing smaller lines as each line is only needed for that fixture. Because of this layout, that will help eliminate or reduce the issues caused when water is called for from multiple fixtures at once & the waiting period for Hot Water. The picture shown is the one we used from MANABLOC that has a shutoff for each supply line.

With the introduction of PEX it made it easier on plumbers to utilize what is referred to as a “Home Run System.” A Home Run system is where the water still comes from the same supply line but it runs into a manifold or distribution point. From this manifold a line is run to each fixture generally utilizing smaller lines as each line is only needed for that fixture. Because of this layout, that will help eliminate or reduce the issues caused when water is called for from multiple fixtures at once & the waiting period for Hot Water. The picture shown is the one we used from MANABLOC that has a shutoff for each supply line.

There are numerous variants of these systems, from one major supply line feeding two or more manifolds to a supply line being split into two and feeding both ends of a single manifold. Generally these are not seen except on larger houses where one might have two or more Hot Water heaters, or they are utilizing a radiant heating system.

Closing Thoughts:

While there are many other solutions for running water to your fixtures, one can easily see why I generally will spec out PEX tubing as my first choice. While they do make fittings for DIY applications, this is one area where a skilled plumber would be my first recommendation. The great work shown above (and plenty that isn’t shown in the pictures) is from Davis Plumbing in Birmingham, Alabama.

Sean – good intro to manifold plumbing, although hot water systems are a lot more complicated than most people think, and studies have shown that home run systems are often less efficient than well designed home run systems. This is often due to the very thing that makes PEX easy to install – its flexibility – allowing plumbers to run long lengths in any direction. I’ve also seen installations where hot and cold water lines are bundled together, significantly reducing efficiencies. All hot water pipes should be insulated and pipes runs should be as short as possible. Check out this web page, it has links to several excellent articles on the subject by Gary Klein, probably the best source of information on residential plumbing. http://www.a4we.org/Residential_Hot_Water_Distribution_System_Introduction.aspx

Thanks Carl for the comment & the link – I will definetly have to check that out further. As an FYI, I added you to the White List so any comments with links in them don’t sit in the moderation queue forever.

Good point on the bundling of hot & cold together & running longer runs than required – this was not an issue with Davis Plumbing, as they did it right. As I said, I will have to review the site you provided, but I am not fully sold that the lines always need to be insulated – especially when they are in the building envelope.

The

secret behind the success of PEX is hidden in a particular variety of

High Density Polyethylene (HDPE). It is this HDPE which is used to

create the tough PEX tubing. This is the new age material that is gained

much favor and popularity among tube manufacturers who have chosen PEX

over other traditionally used materials like iron, lead and plastic.

PEX

is available in three types which are categorized – A, B and C. These

are merely methods to identify the manufacturing process and the

requirements that you have in mind. That is why, selection of PEX tubing

is to be done with your requirements in mind. The skill level required

for your�plumbing, the budget of your project, tools and materials to be

used for plumbing.

About the Author

Warm Floor Center is the best place online to shop for all

your Radiant Heating & Radiant Floor Heating Supplies. Our main

product lines include pex tubing,

Taco Pumps, Radiant Heat Manifolds, Heat Exchangers, Thermostats, Heat

Transfer Plates and Takagi Tankless Water Heaters for Warm Flooring. For

more details on pex plumbing please visit our website.

PEX Plumber

RSS Feed

Report Article

Publish Article

Print Article

Add to Favorites

Re-piping should be done when there are damages in pipes so that spoilage of water will be prevented. Pipes are the passageways of water, hence they should be kept right.

Any question re Homeowners insurance and companies refusing to insure if PEX installed??????

There shouldn’t be but… Some locations most notably Chicago & some areas in Cali have fought long & hard against it (Union Pipe Shops most notably). There also was an issue way back with Polybutylen (similar but completely different product) where every single house had to be re-piped which caused some consternation. This may lead some companies to consider it a risk, but most I know of don’t even ask what products are used.

As for it being risky, much less uninsurable the numbers back up the product & show that there is less risk using it. While it can still freeze it is much more forgiving than copper, cpvc & pvc. Unlike the product listed above, these systems have been installed since the 60’s & one is still running just fine in a testing center.

If an insurance company pitches a fit (besides letting me know who & where) I would recommend that someone contact a manufacturer directly for testing data & help.

FYI: The manoblock photo appears to be an improper installation, per the book provided with it, maybe this is a new requirement… There should be supports for each line going into the manifold. A suggested method is for the manifold to be mounted to plywood with 2×4 spacers on either side to support the lines. It looks like there is plenty of room around this one WRT strain from the line, but that wont protect it as years pass and people move and bump the lines around. -Cheers

Good point Alan & thanks for jumping in. While I can’t say for certain, part of me says it wasn’t part of the directions back then. As for it being bumped, I am not to concerned about that due to its location,

I am very amazed by the information of this blog and i am glad i had a look over the blog. Thank you so much for sharing such great information. It really helped me a lot.

Re-piping should be done when there are damages in pipes so that spoilage of water will be prevented. Pipes are the passageways of water, hence they should be kept right.

Thanks Carl for the comment & the link – I will definetly have to check that out further. As an FYI, I added you to the White List so any comments with links in them don’t sit in the moderation queue forever.

Good point on the bundling of hot & cold together & running longer runs than required – this was not an issue with Davis Plumbing, as they did it right. As I said, I will have to review the site you provided, but I am not fully sold that the lines always need to be insulated – especially when they are in the building envelope.

The

secret behind the success of PEX is hidden in a particular variety of

High Density Polyethylene (HDPE). It is this HDPE which is used to

create the tough PEX tubing. This is the new age material that is gained

much favor and popularity among tube manufacturers who have chosen PEX

over other traditionally used materials like iron, lead and plastic.

PEX

is available in three types which are categorized – A, B and C. These

are merely methods to identify the manufacturing process and the

requirements that you have in mind. That is why, selection of PEX tubing

is to be done with your requirements in mind. The skill level required

for your�plumbing, the budget of your project, tools and materials to be

used for plumbing.

About the Author

Warm Floor Center is the best place online to shop for all

your Radiant Heating & Radiant Floor Heating Supplies. Our main

product lines include pex tubing,

Taco Pumps, Radiant Heat Manifolds, Heat Exchangers, Thermostats, Heat

Transfer Plates and Takagi Tankless Water Heaters for Warm Flooring. For

more details on pex plumbing please visit our website.

PEX Plumber

RSS Feed

Report Article

Publish Article

Print Article

Add to Favorites

Any question re Homeowners insurance and companies refusing to insure if PEX installed??????

There shouldn’t be but… Some locations most notably Chicago & some areas in Cali have fought long & hard against it (Union Pipe Shops most notably). There also was an issue way back with Polybutylen (similar but completely different product) where every single house had to be re-piped which caused some consternation. This may lead some companies to consider it a risk, but most I know of don’t even ask what products are used.

As for it being risky, much less uninsurable the numbers back up the product & show that there is less risk using it. While it can still freeze it is much more forgiving than copper, cpvc & pvc. Unlike the product listed above, these systems have been installed since the 60’s & one is still running just fine in a testing center.

If an insurance company pitches a fit (besides letting me know who & where) I would recommend that someone contact a manufacturer directly for testing data & help.

FYI: The manoblock photo appears to be an improper installation, per the book provided with it, maybe this is a new requirement… There should be supports for each line going into the manifold. A suggested method is for the manifold to be mounted to plywood with 2×4 spacers on either side to support the lines. It looks like there is plenty of room around this one WRT strain from the line, but that wont protect it as years pass and people move and bump the lines around. -Cheers

Good point Alan & thanks for jumping in. While I can’t say for certain, part of me says it wasn’t part of the directions back then. As for it being bumped, I am not to concerned about that due to its location,