In last week’s article on Gas Water Heaters we covered the issue of knowledge or should I say lack thereof, of individuals giving advice or doing work that they are not really qualified to give or do. While we briefly covered one of the main issues surrounding Natural Draft Water Heaters, namely the Draft Hood (or Diverter); we didn’t have enough time or space to discuss it fully. Thus in today’s article I want to spend some time looking at what it is there for, and hopefully clear up some misconceptions surrounding it.

In last week’s article on Gas Water Heaters we covered the issue of knowledge or should I say lack thereof, of individuals giving advice or doing work that they are not really qualified to give or do. While we briefly covered one of the main issues surrounding Natural Draft Water Heaters, namely the Draft Hood (or Diverter); we didn’t have enough time or space to discuss it fully. Thus in today’s article I want to spend some time looking at what it is there for, and hopefully clear up some misconceptions surrounding it.

After reading the quote from David Richardson blog post in last week’s article, I can see many of you simply shaking your head and wondering why was that ever even allowed… Seriously, why would anyone in their right mind allow for an appliance to keep on working if the flue is blocked and can’t vent outside? Well if you have a “Vent-less” space heater or fireplace in your house, let me turn this around and ask you the same question. Why, I mean don’t they both burn the same fuel, and have the same by-products? Hmmm, maybe we should cover the combustion process first & then get back to the draft hood.

The Combustion Process & its By-Products

No matter what the appliance (Water Heater, Furnace, Stove, Vent-less Space Heater, etc…) or which fuel source (Kerosene, Propane, Natural Gas, etc…) the two main by-products are water vapor & Carbon Dioxide (CO2). If one achieves “complete combustion” no carbon monoxide is produced. In order to achieve “complete combustion,” the fuel source is regulated along with the combustion air to help make sure there is enough oxygen to achieve it.

The problem which leads to Carbon Monoxide (CO) and other by-products being formed is the incomplete burning of the fuel. This is generally caused by a mechanical issue, too much fuel being present, or a lack of needed oxygen. One of the most interesting items that affects the amount of oxygen present & adds to the fuel mix is VOC’s from paint fumes, laundry sheets, gas vapors, etc…

Quick Note: Heh & you probably just thought the reason they didn’t want flammable materials in there was the chance of them catching on fire. Actually that can be an issue, especially with older units. This was just one reason why many Building Departments required them to be installed on pedestals (especially in garages). As an FYI, newer versions of these water heaters, have an FVIR (Flammable Vapor Ignition Resistant) technology (aka a flame arrester) built in that helps to prevent this issue but does nothing to stop the one mentioned above.

The Draft Hood:

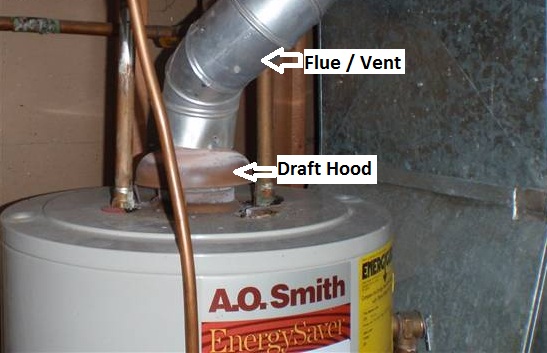

Unlike a “vent-less” fireplace which is expected to heat a room, the water heater needs to evacuate the waste heat (which there is a lot created) & the combustion by-products outside. In order to accomplish this properly, it requires another source of air (aka dilution air) to not only aid the combustion process, but to help cool down the exhaust while not interrupting either the combustion or ventilation process.

The draft hood was created to do this, but primarily to act as a safety feature in case the venting happened to be blocked. The first thing it was designed to prevent was any issues with flame rollout (i.e. flames coming out of the combustion area looking for more air). The second and most important item revolves around a backdraft. While you will hear many of us discussing the issues with fumes and back-drafting, there is one additional type which involves fire & your unit turning into a bomb. This type of backdraft happens when a fire is essentially starving for oxygen & a rapid re-introduction of said oxygen is provided. (i.e. possibly by you opening the door to the room, the access panel, or…) Then there is one final item which is to help prevent items from dropping down into the water heaters flue and combustion area. So if you were wondering, why on earth…, well know you know.