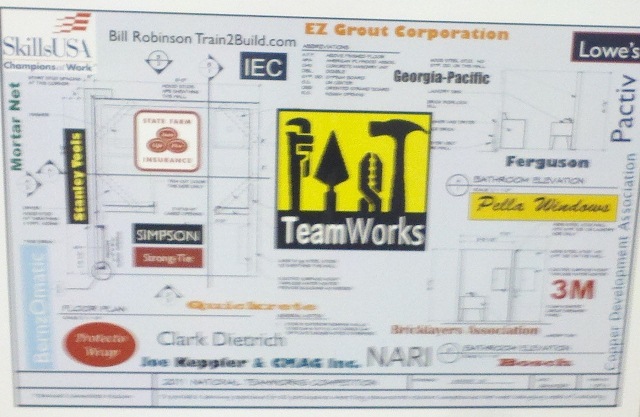

Your mission should you choose to accept it is to allow 5400+ students access to power tools, (that many can’t use per OSHA or State laws till they turn 18) hand tools, and to compete in timed events without having any injuries…. Welcome to the SkillsUSA National Championships for High School & Post-Secondary students. Fortunately, by the time these students have made it to Nationals, they have gone through the safety training required at school, any applicable OSHA courses based on their fields, and generally a regional & state competition with all their associated safety briefings & judging.

Your mission should you choose to accept it is to allow 5400+ students access to power tools, (that many can’t use per OSHA or State laws till they turn 18) hand tools, and to compete in timed events without having any injuries…. Welcome to the SkillsUSA National Championships for High School & Post-Secondary students. Fortunately, by the time these students have made it to Nationals, they have gone through the safety training required at school, any applicable OSHA courses based on their fields, and generally a regional & state competition with all their associated safety briefings & judging.

Whether you are a professional, DIY’er, or a competitor the issues affecting your safety or more importantly others safety are the same and generally revolve around the big three; Trips, Falls, & Cuts. With that in mind I thought we would take a look at some of the items we were paying attention to during this competition & how they help one in real life.

The Work Area:

“Cleanliness is next to godliness” Mr. Hancock – Auto Shop (Back when I knew SkillsUSA as VICA)

There were 5 different items related just to the work area, which not only helps eliminate trip hazards, but allows for a cleaner & more efficient work environment. Make effort to maintain a broom swept area & remove trash to designated areas not only presents a better image to your customers, but helps prevent damaging (via tracking, dinging, etc…) other areas that you may not have budgeted for. This is further brought out with the requirements to stage your materials effectively, your tools, and keeping everything inside the taped off work area.

Tool Usage:

Almost 40% of the judging revolved around tool usage – Used ladder, power tools, hand tools, hammers, and utility knives in a safe manner. I would say it was a testament to not only the students, but their instructors & advisors as to how well all of them did in this category. While I was left shaking my head at a few methods utilized I can only recall one team that actually got dinged in this category. There probably should have been a second team that got dinged but we were not on the floor when the one & only known injury happened within the first 5 minutes (small cut).

PPE (Personal Protective Equipment):

One must wear gloves when working with steel framing, wear a hard hat at all times, and wear safety glasses at all times were the only items judged this year. Unfortunately for most teams, the gloves were a major issue this year as the gloves provided were not the best type to work with those small screws & the steel components. If you think the kids don’t know or care about what should be worn I almost choked when we were doing the final debrief (and the students got to comment on what was good or bad) and one stood up & asked why all the “safety judges” were wearing tennis shoes when they should have been wearing steel toe boots… (Oops maybe because mine were left sitting on the table with everything else I forgot to grab when I was rushing out the door)

Other Items:

Maintained safe working posture, handled materials in a safe manner, refrained from conferring with spectators, and maintained good safety practices throughout the competition while a little nebulous are good items one has to remember throughout the day, as all it takes is one second of inattention. In both cases where I have been injured (enough to require or have recommended a trip to the hospital), it has always fallen into this category and that one second.

Can we stop this madness?

To all students, educators, advisors, and tradesmen – can we please stop this or at least put the nails above the six-foot mark? While I understand the desire of not bending down to grab the hard hat or tool belt, how many ripped shirts, cuts, eyes, etc… do we have to live with?

To all students, educators, advisors, and tradesmen – can we please stop this or at least put the nails above the six-foot mark? While I understand the desire of not bending down to grab the hard hat or tool belt, how many ripped shirts, cuts, eyes, etc… do we have to live with?