For this week’s Safety Sunday Article, I am turning the reigns over to Paul Hamtil of Hamtil Construction located in St. Louis. Hamtil Construction is also a family owned business that believes “Building a Tradition of Quality“and it shows (Portfolio). Now if your asking why is he discussing ladders, I encourage you to read on…

For this week’s Safety Sunday Article, I am turning the reigns over to Paul Hamtil of Hamtil Construction located in St. Louis. Hamtil Construction is also a family owned business that believes “Building a Tradition of Quality“and it shows (Portfolio). Now if your asking why is he discussing ladders, I encourage you to read on…

I t all begins with the saying “The right tool for the right job”. Ladder use is no exception to this guideline, as the selection of a ladder by size and type can make or break a safe job. As I spend a lot of time working on ladders, I have become fairly comfortable with their use. A recent event showed me, however, to never let my guard down. My Dad was hanging a swing in a backyard tree, when the branch he was leaning his ladder against broke and caused him to fall and injure his back. My Dad was only one of the estimated 500,000 people who are injured annually while using a ladder, and is included in the approximately 164,000 people whose injuries land them in the Emergency Room according to the Consumer Product Safety Commission.

t all begins with the saying “The right tool for the right job”. Ladder use is no exception to this guideline, as the selection of a ladder by size and type can make or break a safe job. As I spend a lot of time working on ladders, I have become fairly comfortable with their use. A recent event showed me, however, to never let my guard down. My Dad was hanging a swing in a backyard tree, when the branch he was leaning his ladder against broke and caused him to fall and injure his back. My Dad was only one of the estimated 500,000 people who are injured annually while using a ladder, and is included in the approximately 164,000 people whose injuries land them in the Emergency Room according to the Consumer Product Safety Commission.

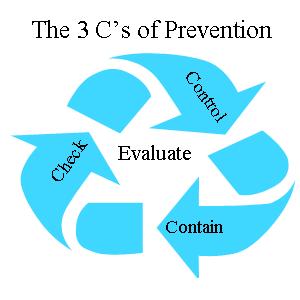

As put forth in The 3 C’s of Prevention, one must evaluate the task at hand. While working for a local Parks Department at one of my first jobs, I watched a coworker set up an 8’ stepladder on top of scaffolding to reach a soffit at the pool we were painting. The ladder became wobbly, and he fell and broke his leg. It’s not hard to see that if he had stepped back and evaluated the situation and risks, there were several better options.

As put forth in The 3 C’s of Prevention, one must evaluate the task at hand. While working for a local Parks Department at one of my first jobs, I watched a coworker set up an 8’ stepladder on top of scaffolding to reach a soffit at the pool we were painting. The ladder became wobbly, and he fell and broke his leg. It’s not hard to see that if he had stepped back and evaluated the situation and risks, there were several better options.

General:

Ladders are available in aluminum and fiberglass. Aluminum ladders are lightweight, less expensive, and for general use. Fiberglass is a good choice for working near electrical hazards (it’s non-conductive), and are generally more heavy duty, but cost more.

Take caution to observe the duty ratings of ladders. Duty rating is defined as the maximum safe load capacity of the ladder. This is the total weight of the user and all tools and materials, which must be under the rating.

Use all ladders on level and stable surfaces, and observe the maximum working height guidelines posted on the label.

Step Ladders:

Stepladders range from 2’-12’ and taller. Because they have different feet than an extension ladder, they are meant to be used open, and not leaning against a wall. Stepladders have maximum working heights to observe, and of course, NEVER stand on the top platform or on the rungs. Also, from personal experience, do not ever leave items laying on the top or rungs of the ladder. An unsuspecting person can jolt it free or move the ladder, potentially resulting in a head injury!

Stepladders range from 2’-12’ and taller. Because they have different feet than an extension ladder, they are meant to be used open, and not leaning against a wall. Stepladders have maximum working heights to observe, and of course, NEVER stand on the top platform or on the rungs. Also, from personal experience, do not ever leave items laying on the top or rungs of the ladder. An unsuspecting person can jolt it free or move the ladder, potentially resulting in a head injury!

Extension Ladders:

Extension ladders, which range in height from 16’- 40’, are used to reach places much higher than a stepladder. One concern with these is the proper slope when setting up. The suggested ratio is 1’ from the wall at the bottom for each 4’ of elevation. When using up to the roof line or similar point of contact, extend the rails 3’ beyond said point. Many accidents occur by persons carrying too many tools or materials up with them, so a hoist rope with a bucket attached is a good alternative! One trade tip is if you are planning to work near electrical lines, you can contact your local utility to have rubber “line cover” put on the wires to avoid accidental contact.

Extension ladders, which range in height from 16’- 40’, are used to reach places much higher than a stepladder. One concern with these is the proper slope when setting up. The suggested ratio is 1’ from the wall at the bottom for each 4’ of elevation. When using up to the roof line or similar point of contact, extend the rails 3’ beyond said point. Many accidents occur by persons carrying too many tools or materials up with them, so a hoist rope with a bucket attached is a good alternative! One trade tip is if you are planning to work near electrical lines, you can contact your local utility to have rubber “line cover” put on the wires to avoid accidental contact.

Accessories:

There are many accessories to help use ladders safely. Such items include, but are not limited to leveling legs, stabilizer bars (pictured), paint trays, hook systems, rubber boots, etc. However, nothing beats a best friend holding you tightly at the ground!

There are many accessories to help use ladders safely. Such items include, but are not limited to leveling legs, stabilizer bars (pictured), paint trays, hook systems, rubber boots, etc. However, nothing beats a best friend holding you tightly at the ground!

Additional Info & Web Sites:

I would like to thank Paul for not only writing but posting his first ever blog article on our site. If you happen to be on Twitter, I would encourage you to @hamtilconst a follow & here’s hoping that your dad fully recovers soon.