As many know the ENERGY STAR program has recently underwent a major upgrade from just ENERGY STAR (ES) to ES3. During that time over 4300 builders, 900 raters / verifiers & 330 HVAC contractors completed the necessary steps to learn & comply with the new guidelines. During this period many of us participating forwarded questions, comments, and concerns to the ES3 program coordinators. With that feedback, the ES3 team ended up revising the program as required 4 times before it went live on January 1st, 2012.

As many know the ENERGY STAR program has recently underwent a major upgrade from just ENERGY STAR (ES) to ES3. During that time over 4300 builders, 900 raters / verifiers & 330 HVAC contractors completed the necessary steps to learn & comply with the new guidelines. During this period many of us participating forwarded questions, comments, and concerns to the ES3 program coordinators. With that feedback, the ES3 team ended up revising the program as required 4 times before it went live on January 1st, 2012.

With the program now going live it has become necessary for them to issue a 5th revision to help clarify some issues & to help make the process a little smoother for those transitioning to the new system. While this revision is not mandatory for any house permitted before March 15th, I can’t really see anyone not adopting these revisions almost immediately. With that, here are some of the major changes that have been made…

The Thermal Enclosure System Checklist

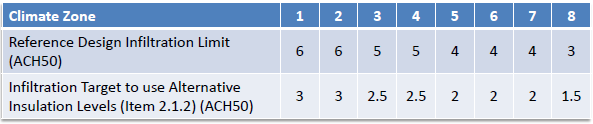

- 2.1 — If the house is built “very tight” (see chart below) or is 50% better than the reference design limit, one can now perform a tradeoff for insulation levels (performance or prescriptive path). For example in our area where some builders don’t like adding insulation under the slab, they no longer have to if they , meet the UA alternative measurement & the ACH50 is at 2.5 or less.

A total building thermal envelope UA that is less than or equal to the total UA resulting from the U-factors in Table 402.1.3 also complies. The insulation levels of all non-fenestration components (i.e., ceilings, walls, floors, and slabs) can be traded off using the UA approach under both the Prescriptive and the Performance Path.

- 3.2 — Grade 1 use is no longer a requirement for batts used in floor cavities if the only issue is compression, but it must be enclosed on all 6 sides – seriously folks go with a sealed crawl, especially in a humid environment

- 4.1 — Raised heel trusses are not required just yet… Based on the Southern Pine span issue & some builders still needing to evaluate & implement the changes, they have been given a temporary reprieve (until the end of this year) to meet the full requirement. As of now in climate zones 1 – 5 you only need an R15 instead of 21 and 21 instead of 30 for our northern neighbors.

- 5.2 — Can I get an amen? They have actually changed the caulk only wording (for air sealing sills, top plates & drywall) to allow for caulk, foam or equivalent material. As for drywall, this is the only time construction adhesive is listed as a no-no, but they now list drywall adhesive as approved.

HVAC System Quality Installation Contractor Checklist:

- The HVAC designer no longer needs to be ES3 credentialed, but the builder must remember that they are responsible for the overall design, data, and information provided. With that said the installer (if different) is not responsible for filling out sections 1-5, rather the builder or designer is.

- A ES3 credentialed installer must install and test the system, which also means that they are responsible for filling out sections 6 – 12

- No forced air system- complete section 1 & you are done

HVAC System Quality Installation Rater Checklist:

- 2.8 — Bedroom Pressure Balancing Test – apparently there has been some disagreements on how this is to be completed, so they have spelled out there method. To complete this test ALL bedroom doors must be closed with ALL the air handlers turned on. If these units have multi-speed fans they must ALL be on HIGH. The result must be less than 3 pa difference WRT the main house.

- 4.1 — the first WTF, but some contractors will be very happy as they raised the allowable duct leakage from 6 CFM per 100 SF to 8cfm @ 25pa. Personally with the 2012 codes requiring 4% across the board it probably should have stayed at 6% to help them prepare

- They did remove the “you must seal all boots to the drywall” as they figure that will be done for the most part to get below the duct leakage number & they would hate for a unit to fail in case one was missed…

- Now onto the second WTF – due to some other ambiguity on the duct testing side, one can also seal around the perimeter of the register grill & not just the face when running the test. I guess part of that is due to all those companies making shoe-box style covers for testing instead of just using grill tape. Word of warning, they are looking into clearing this up and who knows which way it will go… IMHO, while there really is no chance of messing up most properly installed finishes, if you are using grill-tape I would suggest keeping it off them & only apply it to the grill.

More Information & Resources:

- ENERGY STAR V3 Guidelines

- Updated Fillable Checklists (combined)

- Record’s & Revisions

- Email: energystarhomes@energystar.gov

- Twitter: @energystarhomes

- AlaGBS – Alabama ENERGY STAR Verifier

- Energy Vanguard – ENERGY STAR Trainer & Provider