Thank goodness for rain days as this Thursday that allowed me to get back up to Athens to check out the progress and help out for a few hours. Along the same lines, I thought I would include more about BOULD’s system & how it works. For more on this project you may wish to review; Becoming a LEED AP, Let’s get this project started, Weather & Scaffolding, and Let the concrete flow.

Thank goodness for rain days as this Thursday that allowed me to get back up to Athens to check out the progress and help out for a few hours. Along the same lines, I thought I would include more about BOULD’s system & how it works. For more on this project you may wish to review; Becoming a LEED AP, Let’s get this project started, Weather & Scaffolding, and Let the concrete flow.

As you may recall, when we last were at the project, the concrete was just poured for the walls and supports were still in place. 1 month later as you can see, all the supports are gone and the roof is now dried in. It will soon have standing seam panels applied which will be great if they can get the solar system installed as they have special clips which eliminates any fasteners being drilled into the roof.

Just a quick shot of the trusses…

Can you say oops – one quick lesson is to always double check your measurements. Yes that is three top plates you see as they framed the walls in this case regularly & realized that the top plate attached to the ICF’s added an additional 1.5 inches of height that was not accounted for when the slab was poured. I am sure it made standing them walls up though feel like child’s play.

One of the reminders of those who help make Habitat the organization it is…

Unfortunately today was a short day at the project, so after we called it a day Greg Miller was nice enough to show off one of their other project before we headed out for lunch. Along the unfortunate parts though is I failed to get a shot of the outside,but fortunatly you can see it in this video from the students at WKU who helped pour the concrete & signed the wall above.

This is a pic from the front bedroom at the panelized construction the generally employ.

A shot of the jumper ducts run into each bedroom to help keep the HVAC working properly (yes this is also an ENERGY STAR & LEED home)

Ok, seriously USGBC, they have to install a duct into the attic why? Sealed Crawl spaces- yes, Hot roof systems are a not required. Interestingly enough, this 1200+ SF house with a nice open floor plan only requires a 1 ton system which one cannot unfortunately purchase so they had to go with a 2-ton variable speed unit. Hint, hint TRANE, Carrier, et al…

BOULD’s EverBuildPRO System:

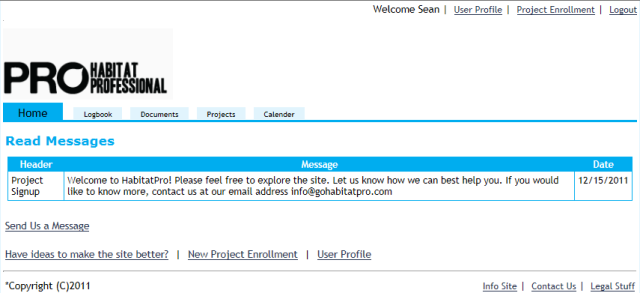

As you may recall, as part of the program one must put 50 hours in on the project. In order to do this, it is all web based & this is the screen you see when you log in. The top section is pretty self-explanatory and where you can choose a project to work on. Under the PRO logo is where the meat & potatoes of the operation happens.

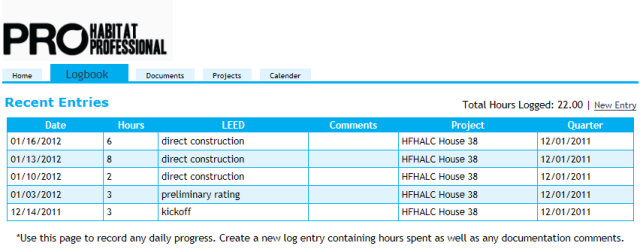

The Log Book allows you to track the hours one spends on each part of the project you work on.

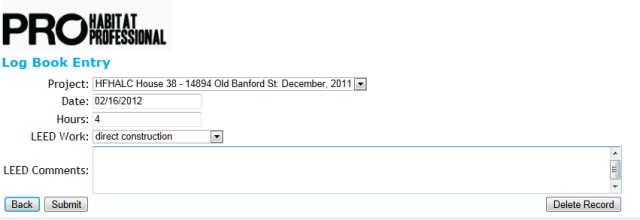

To add an entry you simply click “new entry” and fill out the form shown here.

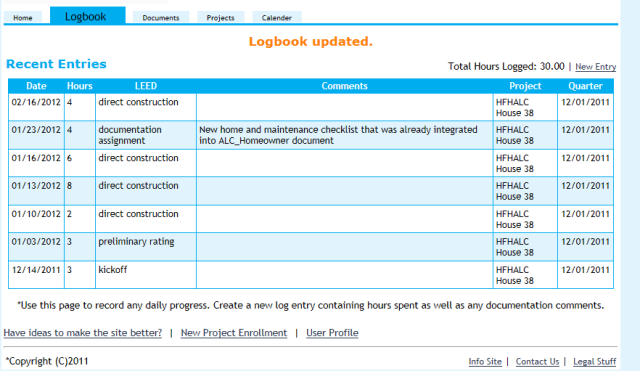

Once you have put in any new hours they automatically become part of the log book.

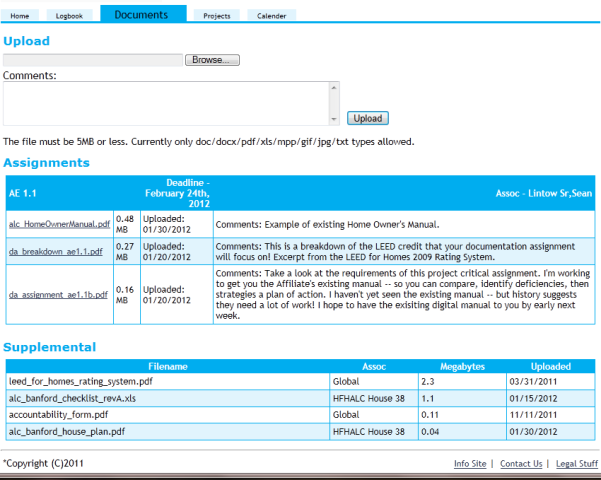

As everyone knows, documentation is key for almost every green certification out there & LEED loves there documents. In this case this is where you are given your task & can upload your work.

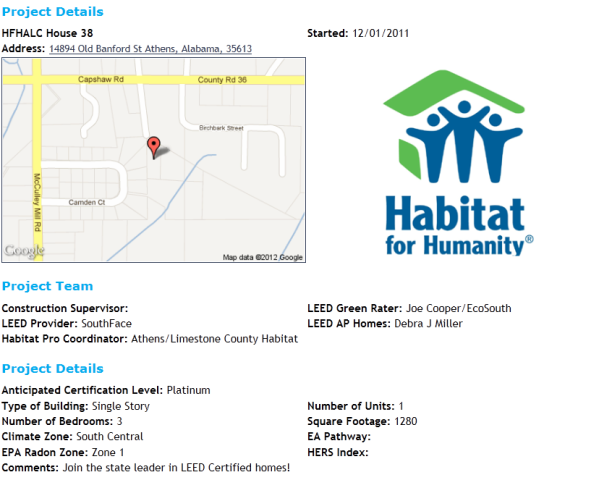

The Projects Tab simply shows which project(s) you are working on & gives some pertinent info. As for the calendar tab, that basically shows past & upcoming meetings. In closing, I have to give the system high marks for ease of use and having the data one needs always available. To top it off any questions or concerns I have had have been answered promptly, so well done BOULD.