This last week marked SkillsUSA 50th year with the Nationals (NLSC) now being held in Louisville, Kentucky. One of the nice things about this is that the TeamWorks event (a team of 4 – one carpenter, an electrician, a plumber & a mason work to complete a project in less than 2 days) isn’t being held a few miles away from almost all the other events, but now is right in with the others.

This last week marked SkillsUSA 50th year with the Nationals (NLSC) now being held in Louisville, Kentucky. One of the nice things about this is that the TeamWorks event (a team of 4 – one carpenter, an electrician, a plumber & a mason work to complete a project in less than 2 days) isn’t being held a few miles away from almost all the other events, but now is right in with the others.

This marks the 5th year I have been involved and my 4th year as a guest judge for the TeamWorks event. While I would have love to have gotten a time-lapse of the entire event, that wasn’t feasible this year due to my schedule & the actual layout of the event. (For prior years: 2012 time-lapse & 2013 time-lapse) With that said, here are some pictures I managed to take. Hopefully in a few more days I will have a second piece up on some of mine & others takeaways plus a few other shots from the floor.

Judging may start on Tuesday but…

Most teams need to arrive on Monday to get signed in, learn where & when they are competing, and to get set for the Opening Ceremonies. With that the hero’s in my book are the Courtesy Corp who really make sure that the event is ready to go. For them, the competition starts on Saturday. (No they have no choice on shirt colors – today’s was pink.)

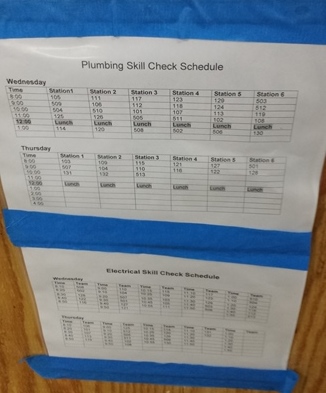

A look at just some of the behind the scenes organization.

Needless to say with 45 teams we eat up a lot of space – the competition floor is one football field out of the 20 for all the competitions.

Orientation / Presentation Day:

Tuesday: Orientation is followed up by the Presentations where every team has to sell themselves. Think it doesn’t matter… well in a first we actually had two guest judges I actually remembered as competitors – one of them was saying how they lost any chance of medaling just because of this. They had top marks in every aspect but that one causing them to come in 5th.

Wednesday: Build Day 1

Today is where the rubber meets the road & welcome to two new surprises.

The first is a Skills Challenge for the electrician & plumber. For the plumber – build a specific copper sculpture that will hold 100 psi. QUICK TIP: the real reason why one wipes the joints is not so that it looks nice (though that is a great side benefit) it is to actually ensure all gaps / pinholes are filled in. For the electricians it is to use a regular plug tester & identify the issue (2 ways).

The first is a Skills Challenge for the electrician & plumber. For the plumber – build a specific copper sculpture that will hold 100 psi. QUICK TIP: the real reason why one wipes the joints is not so that it looks nice (though that is a great side benefit) it is to actually ensure all gaps / pinholes are filled in. For the electricians it is to use a regular plug tester & identify the issue (2 ways).

For the second surprise, while many teams normally decided to wait to complete the roofs on the second day they couldn’t anymore… Yep just like a real site – everything had to be dried in before the “rough-ins” could be started.

Day 1: 30 minutes to start / they are in their daily briefing

Day 1 – 8:55

Day 1 – 10:00

Day 1 – 11:20

Day 1 – almost lunch time

Day 1 @ 1:45 – 15 minutes to go

Thursday: Build Day 2

Thursday is crunch time for not only the competitors but the judges also. This year my primary responsibility was for “plumbing” and as I had to leave ASAP after today I was only able to snap a few pics.

Day 2 Lunch Time

Day 2 Lunch Time

Needless to say they are not completed as what comes up must come down but that is for Friday… For a transition year I got to say it ran pretty smoothly & in many ways better than before though there are always a few time issues & “we can do better.” From everyone I talked with they learned a lot, had fun & it will help them out in the future so chalk that up as a win. Major kudos to all