Lately there have been numerous questions on the use of WRB’s or Weather Resistive Barriers. For example; do I need it if I am using foam? If I am installing foam, should it be placed over the foam or under it? According to the ZIP system, I don’t need one, is this really a good way to go? Then of course the ever famous should I use tar paper or Tyvek?

Lately there have been numerous questions on the use of WRB’s or Weather Resistive Barriers. For example; do I need it if I am using foam? If I am installing foam, should it be placed over the foam or under it? According to the ZIP system, I don’t need one, is this really a good way to go? Then of course the ever famous should I use tar paper or Tyvek?

The original WRB was tar paper. While some believe that the original product was made from cotton rags or felt, the original was made generally from squares of paper way back in the 1800’s & used during the gold rush period & even on the prairies for shanties & roofing. This product soon evolved into being made in rolls using felt, then fiberglass & now we are back to using paper, albeit a very specialized paper. While this product has evolved, other products started to be developed back in the 70’s to replace it & help solve some shortcomings (tearing, made from oil, etc…). The most notable of these was produced by DuPont & called Tyvek which has now become shorthand for housewraps. The newest incarnations revolve around sheathing with an integrated barrier & a sprayed on type. The original WRB was tar paper. While some believe that the original product was made from cotton rags or felt, the original was made generally from squares of paper way back in the 1800’s & used during the gold rush period & even on the prairies for shanties & roofing. This product soon evolved into being made in rolls using felt, then fiberglass & now we are back to using paper, albeit a very specialized paper. While this product has evolved, other products started to be developed back in the 70’s to replace it & help solve some shortcomings (tearing, made from oil, etc…). The most notable of these was produced by DuPont & called Tyvek which has now become shorthand for housewraps. The newest incarnations revolve around sheathing with an integrated barrier & a sprayed on type. |

Why do we need WRB’s?

Water is the houses biggest enemy & if we expect them to stand the test of time we need our structures to be designed & built properly for the environment. In order to do this we need to deflect water away from the structure, & deal with any that does get in, by having a way for it to drain away and to dry out. While the exterior cladding is great at deflecting water, it isn’t water proof & is a great place for condensation to form.

This brings us to two of Joseph Lstiburek’s “perfect” wall assemblies control layers – the air control & vapor control layer. Many people consider a WRB only as a water control layer & thus change the term to Water Resistant or Resistive Barrier, but if installed properly it also can also act as an air control layer. The biggest catch with relying on it as an air barrier is where it has to be completely taped & sealed to the foundation & ceiling air barriers.

Then of course we have the code: 703.1 (2009 IRC) Exterior walls shall provide the building with a weather-resistant exterior wall envelope. .1 goes on to state that it must “be designed and constructed in a manner that prevents the accumulation of water within the wall assembly by providing a water-resistant barrier behind the exterior veneer as required by Section R703.2 and a means of draining to the exterior water that enters the assembly. Protection against condensation in the exterior wall assembly shall be provided in accordance with Section R601.3 of this code. Then of course we have the code: 703.1 (2009 IRC) Exterior walls shall provide the building with a weather-resistant exterior wall envelope. .1 goes on to state that it must “be designed and constructed in a manner that prevents the accumulation of water within the wall assembly by providing a water-resistant barrier behind the exterior veneer as required by Section R703.2 and a means of draining to the exterior water that enters the assembly. Protection against condensation in the exterior wall assembly shall be provided in accordance with Section R601.3 of this code. |

Foam as a WRB?

While it is possible for foam to function as a WRB, per 703.2 it must meet ASTM D 226 guidelines first & be installed “in a manner to meet the requirements of the exterior wall envelope” as described above which means in the same manner as it was tested. On the flip side of this is the unhappy little fact that we build in the real world & our structures are tested there also, not just in a lab so if you do wish to go this route, I would recommend two layers with the seams being offset and taped. (e.g. if codes or the specs call for R10 – go with two layers of R5)

If you have ever worked on a historic building, you might have noticed or more items missing like insulation, sheathing & tar paper. Most of these structures still continue to stand today so the question starts to become, why? Well these older structures continue to stand because of their design; if & when they get wet, they could dry out very quickly as the framing cavities were empty. It also helped that the materials used back then were from old growth lumber with a real tight grain. So before you just jump in & insulate one, make sure you know that there are no water issues before you get started and if there are, you need to get them solved first. If you have ever worked on a historic building, you might have noticed or more items missing like insulation, sheathing & tar paper. Most of these structures still continue to stand today so the question starts to become, why? Well these older structures continue to stand because of their design; if & when they get wet, they could dry out very quickly as the framing cavities were empty. It also helped that the materials used back then were from old growth lumber with a real tight grain. So before you just jump in & insulate one, make sure you know that there are no water issues before you get started and if there are, you need to get them solved first. |

Foam over or under the WRB?

The first factor to consider is what does the manufacturer recommend? With that said many products like Tyvek say it doesn’t matter, while all the pictures show it being under the foam. In most cases I would recommend it should be under the foam as there have been complaints that when the foam starts expanding & contracting (yes it does that) you could actually hear it inside. In this case the Tyvek simply acts as a bond break & allows the materials to move easier. With that said the best place is dependent on where you install the windows. If they are mounted in the cavity or attached to the sheathing the foam should be over the WRB which is integrated with the window flashing. Now if you are doing an “outsie” window where the window is mounted outside the foam, the WRB should be outside the foam also so it can properly handle any water.

The first factor to consider is what does the manufacturer recommend? With that said many products like Tyvek say it doesn’t matter, while all the pictures show it being under the foam. In most cases I would recommend it should be under the foam as there have been complaints that when the foam starts expanding & contracting (yes it does that) you could actually hear it inside. In this case the Tyvek simply acts as a bond break & allows the materials to move easier. With that said the best place is dependent on where you install the windows. If they are mounted in the cavity or attached to the sheathing the foam should be over the WRB which is integrated with the window flashing. Now if you are doing an “outsie” window where the window is mounted outside the foam, the WRB should be outside the foam also so it can properly handle any water.

Zip System:

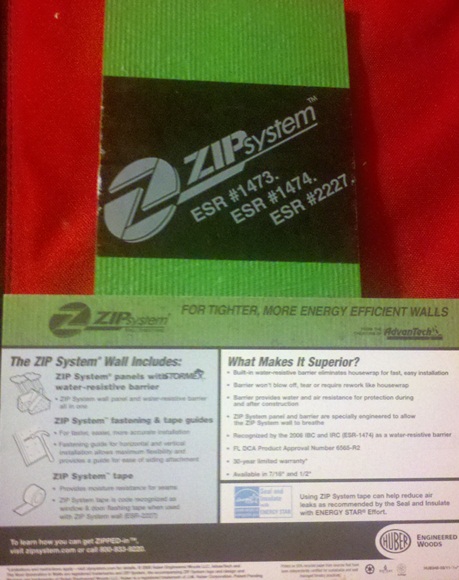

On a closed discussion on Linked In a question popped up about the Zip Wall System, & trusting the tapes / integrated WRB (yes it passed the test.) My reply was pretty simple – “Long term results… Zip walls have only been out for what, 5 years now so it will be awhile before we really know. Based on their testing they are pretty confident that it will hold up. I know the earlier products had a problem with edge swelling if they got the least bit moist, but that appears to have been corrected. I think what we will find is many of them do hold up, while there will probably be a few that fail due to overdriven nails, flashing errors &/or where the tape was bubbled up due to dirt, creased in install, etc…”

A look at the Zip Wall system – the green part is the integrated WRB while the tape is used to not only stop moisture transfer, but also to stop air-leakage

A look at the back

While we will get into sheathing in another article, the biggest issue is sheathing requires a 1/8″ gap for expansion & contraction – in order to allow for this you can see they did this with a ridge in the center as shown above.

While there are many fans including Joseph Lstiburek who echoed some stronger sentiments than what was seen on “This Old House” in support of the product (i.e. no additional WRB needed) he also offered some words of caution “no product is perfect and no product application is perfect. The biggest problem with tapes is using them at window interfaces and teaching the trades’ origami. They are not fast and require warm dry dust free surfaces…”

Personally I like the concept behind zip-wall, but when it comes to exterior walls & roofs I still like the belt & suspenders approach. With that I rather see a product like Benjamin Obdyke’s HydroGap be used over it to ensure drainage, no issues & prevent issues with solar drive.

Speaking of “This Old House”, I was quite impressed with the details they were using around a window & the wall, until this… Speaking of “This Old House”, I was quite impressed with the details they were using around a window & the wall, until this… Yeah can you say oops – from our Drying in the Roof article “Staples (i.e. slap staplers) have been removed as a valid means of fastening the underlayment quite a few years ago… There are four main reasons that one should use tabbed or cap nails; its code in many locations, most manufacturers require it, staples can actually cause water to leak through due to capillary action, and finally nails have a greater hold down power. Now if you wish to still use staples, they make specialty cap-staplers which can be used in many cases or you must use a 1” minimum crown staple.There is one interesting caveat to this & that is with Benjamin Obdyke’s HydroGap product – because of the gap & its composition one can use a slap stapler, though you need to be careful that you don’t damage it with the nose. Yeah can you say oops – from our Drying in the Roof article “Staples (i.e. slap staplers) have been removed as a valid means of fastening the underlayment quite a few years ago… There are four main reasons that one should use tabbed or cap nails; its code in many locations, most manufacturers require it, staples can actually cause water to leak through due to capillary action, and finally nails have a greater hold down power. Now if you wish to still use staples, they make specialty cap-staplers which can be used in many cases or you must use a 1” minimum crown staple.There is one interesting caveat to this & that is with Benjamin Obdyke’s HydroGap product – because of the gap & its composition one can use a slap stapler, though you need to be careful that you don’t damage it with the nose. |

Speaking of HydroGap – a look at the dimpled product which creates a 1mm gap allowing for water to drain out & cladding to dry easier.

Tar Paper vs. Housewrap vs.…

Oooh with so many choices today, just how does one choose the best product? While there will always be some die-hards that will prefer one over the other it all comes down to installing whichever product is used properly. With that, I have to say I am partial to two layers of tar paper behind regular stucco. I prefer a standard Tyvek like product behind foam or under a rain screen / air gap detail. If one can’t use a rain screen detail then I prefer using a HydroGap product.

With that let me finish off by paraphrase one last point from Joseph Lstiburek who states it is up to the designer / architect to use their judgment by weighing the risks, costs, skill of the installers & ones climate. In most cases the weak link is the choices made & the installation process, not the material. Oh ok, I can’t leave this one out – “Just to be clear Duct Tape has 1001 uses, this is not one of them.”

Informative and well written!

Great article. Keep it up. We have been using ZIP with a vented rainscreen cladding assy, but are now about to try our first exterior foam walls that will take the place of the ZIP system as our WRB and air barrier. Only one layer to start and it’s hard to justify labor expense of two layers, but I do see your point with 2 and Building Science likes to do the same.

Supremely confident in the ZIP system and the butyl tape will last much better than a flash and fill type approach from the inside or many other methods of air sealing. It was studied back in the 70’s a bit if you really dig. Not ZIP. Tape.

Keep it up.

Thanks Scott & Chad for the comments. You are correct Scott, we owe a lot to people like Joe L. & others that were talking about this, rain screens, etc… in the late 70’s & 80’s. Fortunately materials have come a long way since then. Good luck with your project & I would like to hear how it comes out if you don’t mind checking back in (even if it is just with a link to your blog on it)

What about Tung Oil as a finish? This one seems interesting to me: Dilute 50-50 mineral spirit and Tung Oil, paint it into the sheathing, then come back a week later (yes I know, builders hate things that take time) and lay pure tung oil on top.

Tung expands and contracts with the wood, and is flexible. It’s been used to waterproof ships, it resists acids, salts, actone, and so on. The only conceivable problem is the 1/8 gap between sheathing sheets–but this is a different problem than trying to wrap the house so that you don’t get water on the sheathing.

Nice thought John but the catch is not making things waterproof per se but dealing with water & water vapor so it doesn’t get into the framing assembly – the other catch is also making sure any water that does get in has a chance to get out. Granted if water never gets in the issue is mute

In planning my self-build slab on ICF foundation home,I find this article of great interest. I plan to clad exterior with standard painted metal R panel. So 2×4, 16″oc stud wall/ 7/16 osb/ any WRB/install windows and doors /tape seal to WRB/Install metal trim to accomadate, 2 Overlapping layers of 1/2″ foam/ install metal panels?

I am in an area where termite barrier system is a must. Looking for suggestions to above mentioned exterior, am I missing any components?

ICF and foam on walls does not seem the best idea in turning away subterranean termites. Plan to integrate a metal flashing under borate bottom plate to receive the 1″ of foam and metal panels.

Suggestions welcome.

Travis

Thanks Travis & we have done a few pieces on termites before – https://thehtrc.com/2014/bs4d-termites & https://thehtrc.com/2014/termite-insect-shields.

Just remember that the shield needs to stick out far enough as the object isn’t to just fully stop them but to allow you to see their tunnels to know they are there so you can eliminate them (before they get to the wood))

The only thing based on the above is I would try integrating a rain screen detail (assuming that isn’t part of your system) and as always it comes down to the installation (overlapping & offset foam)

Best of luck & shoot photos are always welcome – even a guest piece

Informative and well written!

Great article. Keep it up. We have been using ZIP with a vented rainscreen cladding assy, but are now about to try our first exterior foam walls that will take the place of the ZIP system as our WRB and air barrier. Only one layer to start and it’s hard to justify labor expense of two layers, but I do see your point with 2 and Building Science likes to do the same.

Supremely confident in the ZIP system and the butyl tape will last much better than a flash and fill type approach from the inside or many other methods of air sealing. It was studied back in the 70’s a bit if you really dig. Not ZIP. Tape.

Keep it up.

Thanks Scott & Chad for the comments. You are correct Scott, we owe a lot to people like Joe L. & others that were talking about this, rain screens, etc… in the late 70’s & 80’s. Fortunately materials have come a long way since then. Good luck with your project & I would like to hear how it comes out if you don’t mind checking back in (even if it is just with a link to your blog on it)

What about Tung Oil as a finish? This one seems interesting to me: Dilute 50-50 mineral spirit and Tung Oil, paint it into the sheathing, then come back a week later (yes I know, builders hate things that take time) and lay pure tung oil on top.

Tung expands and contracts with the wood, and is flexible. It’s been used to waterproof ships, it resists acids, salts, actone, and so on. The only conceivable problem is the 1/8 gap between sheathing sheets–but this is a different problem than trying to wrap the house so that you don’t get water on the sheathing.

Nice thought John but the catch is not making things waterproof per se but dealing with water & water vapor so it doesn’t get into the framing assembly – the other catch is also making sure any water that does get in has a chance to get out. Granted if water never gets in the issue is mute